Lean transformation and improvement requires Senior and Executive leadership and participation. Our approach targets specific lean transformation at the Senior and Executive level resulting in greater recognition of potential returns and impact and as a result gains far greater Executive buy-in and participation.

At Lean Business Thinking our services focus in 4 main areas

- High Impact Transformations

- Brilliant Basics

- The Lean Start Up Methodology

- Lean Training - The development of lean thinking skills

Transformation Types

Our experience shows lean improvement and transformation should take place across the whole organisation. If we consider the transformation flag (Source - Masaaki Imai) below, this indicates the type of improvement activities that should take place at different levels of an organisation.

High Impact Transformations

|

Focus only on high priority transformations (The top 3 things the Business Executives care about). Prioritise your most important actions by:

- Strategic objectives

- Customer outcomes (value delivered)

- Cost

- Risk

|

|

When the organisation needs to pivot

Rethinking the organisational boundaries, transforming your business value streams |

Brilliant Basics

Improving your core processes, getting the existing to work properly.

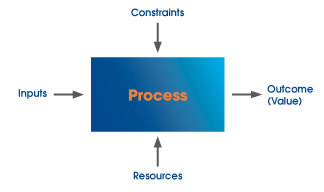

When we consider the process model shown, we work with your teams to improve your process

When we consider the process model shown, we work with your teams to improve your process

- Inputs

- Resources

Transforming your process

- Outcomes

Delivering more value or ensuring better adherence to your process constraints.

The Lean Start Up

For organisations trying to create products and services in extreme uncertainty, we have evolved the methodology of Eric Ries et al. into an actionable methodology for fast growth start ups, or any organisation or entities trying to define and create value but:-

- Do not know the customer

- Do not know the value stream

Our experience working in a number of challenging domains shows applying the Lean Start Up methodology whilst constraining resources can accelerate the growth and increase the likelihood of success for start ups.

The Development of Lean Thinking Skills

Our experience shows an essential ingredient for any successful transformation is to develop the lean thinking skills of our clients, their employees and teams. We embed training in lean tools and techniques as part of the transformation process. For us lean is not just about tools and techniques, but the lean tools help embed lean thinking skills to challenge mindsets and change behaviours. This helps secure buy-in and ensures the transformation is sustained within the business.

The lean thinking skills provided include -

Observation skills - Questioning skills - Pattern recognition - Prioritisation skills - System Thinking - Definition skills - Analysis - Collaboration skills - Problem Solving - Six Sigma - 5 lean principles - Creativity & Innovation - Synthesis.

Lean Transformation

Lean Transformation

We have successfully applied lean transformation and improvement in a wide variety of industry and business contexts. Our approach does not simplistically "force fit" a lean manufacturing approach into our clients organisation. Our experience shows the clients business and functional domains must be carefully analysed to properly understand the value stream levers that will provide the most effective value creation and delivery. This analysis allows us to conceptualise a specific lean approach for the client domain. The diagram adjacent shows some of the business and functional domains in which we have successfully delivered lean transformation and lean thinking skills.

#leanbusinessthinking